A new lightweight version of Raspbian Jessie has been released. It looks promising for “headless” applications (no monitor, keyboard or mouse). I fired it up on my Raspberry Pi Model B.

You can get Raspbian Jessie Lite from

here. At the time of writing, the version was dated 2016-02-09 and the kernel version was 4.1. The ZIP download weighed in at 365MB. This contained a similarly sized compressed IMG file. Next, I had to write this image to SD card.

Note that choosing a reliable SD card is something of a science, with guidance available from various sources. For example, see

here. I chose an 8GByte Lexar micro SD card that came bundled with an SD card adapter. I bought it from Amazon because of their no-fuss returns policy:

|

| Lexas 8GB microSDHC card with SD adapter |

The procedure for writing to image to SD cards can be found

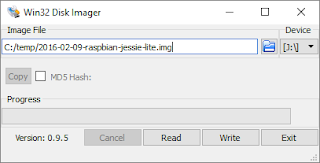

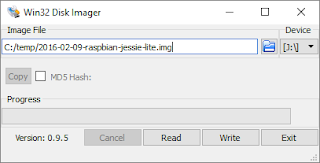

here. I followed the Windows recipe, first extracting the IMG from the ZIP, and then running

Win32DiskImager to write the IMG to my SD card:

|

| Win32DiskImager application |

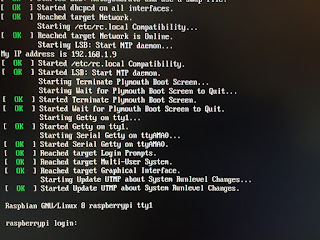

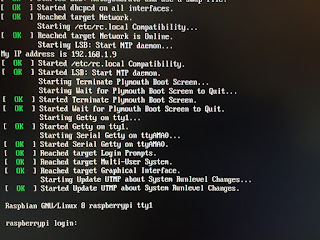

It took a few minutes to get these steps done. I then inserted the freshly written SD card in the Pi, connected it to the HDMI input of my monitor, and plugged in an ethernet cable. Boot messages appeared on the monitor within a couple of seconds of power on. The login prompt appeared after maybe 20-30 seconds:

|

| First Boot |

I then switched my monitor back to displaying the output from my desktop PC, aiming to use an ssh client to interact with the now fully headless Pi. There are

plenty to choose from; my favourite is

PuTTY.

To make life easier on my LAN, I use static IP addresses for various devices, such as my NAS, and including my Raspberry Pi. To do this, I reserve an address in my

DHCP server’s configuration, linking the device's

MAC address to a fixed

IP address. For the Pi I chose 192.168.1.9, as shown on the PuTTY configuration dialog:

|

| PuTTY Launch Window |

After double-clicking the raspberrypi entry (to Open it), I blew past the ensuing security warning by clicking Yes. A terminal window then appeared, and I was then able to log in with the usual default credentials (username = pi, password = raspberry):

|

| PuTTY Terminal Window |

Many images assume a 2GB SD card and size things accordingly, meaning wasted space on larger cards. I checked, and this was indeed the case:

pi@raspberrypi:~ $ df -h

Filesystem Size Used Avail Use% Mounted on

/dev/root 1.3G 912M 281M 77% /

devtmpfs 214M 0 214M 0% /dev

tmpfs 218M 0 218M 0% /dev/shm

tmpfs 218M 4.4M 214M 3% /run

tmpfs 5.0M 4.0K 5.0M 1% /run/lock

tmpfs 218M 0 218M 0% /sys/fs/cgroup

/dev/mmcblk0p1 60M 20M 41M 34% /boot

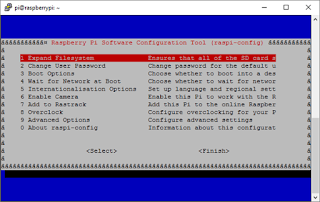

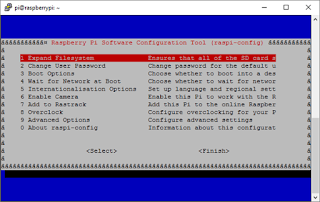

raspi-config can be used to fix this:

pi@raspberrypi:~ $ sudo raspi-config

You simply highlight option 1 and hit Enter...

|

| raspi-config in action |

...and a few seconds later you can reboot and the job is done. I did this, and checked the outcome:

pi@raspberrypi:~ $ df -h

Filesystem Size Used Avail Use% Mounted on

/dev/root 7.3G 913M 6.1G 13% /

devtmpfs 214M 0 214M 0% /dev

tmpfs 218M 0 218M 0% /dev/shm

tmpfs 218M 4.4M 214M 3% /run

tmpfs 5.0M 4.0K 5.0M 1% /run/lock

tmpfs 218M 0 218M 0% /sys/fs/cgroup

/dev/mmcblk0p1 60M 20M 41M 34% /boot

Notice that /dev/root now has 6.1G available.

I will be trying to use the resulting setup for a few embedded projects.